Химия - Пар-жидкость-кристалл - Схожие методы выращивания

01 марта 2011Оглавление:

1. Пар-жидкость-кристалл

2. Введение

3. Механизм роста

4. Схожие методы выращивания

Выращивание с использованием лазера

Involves the removal of material from metal-containing solid targets by irradiating the surface with high-powered short laser pulses, usually with wavelengths in the ultraviolet region of the light spectrum. When such a laser pulse is adsorbed by a solid target, material from the surface region of the target absorbs the laser energy and either evaporates or sublimates from the surface or is converted into a plasma. These particles are easily transferred to the substrate where they can nucleate and grow into nanowires. The laser-assisted growth technique is particularly useful for growing nanowires with high melting temperatures, multicomponent or doped nanowires, as well as nanowires with extremely high crystalline quality. The high intensity of the laser pulse incident at the target allows the deposition of high melting point materials, without having to try to evaporate the material using extremely high temperature resistive or electron bombardment heating. Furthermore, targets can simply be made from a mixture of materials or even a liquid. Finally, the plasma formed during the laser absorption process allows for the deposition of charged particles as well as a catalytic means to lower the activation barrier of reactions between target constituents.

Термическое испарение

Some very interesting nanowires microstructures can be obtained by simply thermally evaporating solid materials. This technique can be carried out in a relatively simple setup composed of a dual-zone vacuum furnace. The hot end of the furnace contains the evaporating source material, while the evaporated particles are carrier downstream, to the colder end of the furnace where they can absorb, nucleate, and grow on a desired substrate.

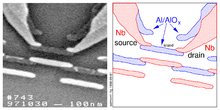

Катализируемая металлом молекулярно-лучевая эпитаксия

Molecular beam epitaxy has been used since 2000 to create high-quality semiconductor wires based on the VLS growth mechanism. However, in metal-catalyzed MBE the metal particles do not catalyze a reaction between precursors but rather adsorb vapor phase particles. This is due to the fact that the chemical potential of the vapor can be drastically lowered by entering the liquid phase.

MBE is carried out under ultra-high vacuum conditions where the mean-free-path of source atoms or molecules is on the order of meters. Therefore, evaporated source atoms act as a beam of particles directed towards the substrate. The growth rate of the process is very slow, the deposition conditions are very clean, and as a result four superior capabilities arise, when compared to other deposition methods:

- UHV conditions minimize the amount of oxidation/contamination of the growing structures

- Relatively low growth temperatures prevent interdiffusion of nano-sized heterostructures

- Very thin-film analysis techniques can be used in-situ, such as reflection high energy electron diffraction to monitor the microstructure at the surface of the substrate as well as the chemical composition, using Auger electron spectroscopy.

Просмотров: 5489

|

|